Efficient Water Heaters

Learn how to design efficient water heaters systems, in compliance with Title 24!

Types of Water Heaters

In your home lies a possible culprit of energy waste, or ‘money down the drain’. You can expect your storage tank heater to last about fifteen years. Of course, these numbers depend on how much water is being used and the integrity of the system(s). If your water heater is old, leaky, or has little or no insulation on it, it might be time to get a new one. So, let’s say you are ready for an upgrade. What are your options? There are three main different types of water heating systems.

Tank

The most common option is a “storage tank” that uses gas or electricity to heat the water and store it in the tank until it is needed. Often, the capacity of tank systems is 30-80 Gallons. 50-60 Gallons are appropriate for 2-3 people and 80 Gallons are better for four people. It’s best to choose a tank that’s accurate to your usage. Otherwise, you risk wasting energy and money on an oversized system.

One of the most efficient water heaters you can purchase without breaking the bank is known as a heat pump water heater. They’re electric or hybrid-style systems that can achieve two to three times the efficiency of a standard water heater. To put that into perspective, your typical tank system might be between 60%-80% efficient. A tankless system is about 80%-97% efficient. Heat pump water heaters outperform both, rated at 200%-300% efficiency.

Tankless

Another option is a wall-mounted tankless water heater. Tankless or demand-type coming more popular because of their efficiency. Since they only provide hot water is needed, they don’t waste energy on storing water. Oh, and you don’t have to worry about your shower turning cold halfway through! You know the saying, “the last one is a rotten egg.” According to Energy.gov, tankless heaters are 8%-34% more efficient on average. While the upfront cost of a tankless heater may be higher, these systems tend to last longer, are easier to fix, and may save money through utility bills over the course of that lifetime.

Solar Water Heater

Energy.gov states that solar water heaters can save 50%-80% on the cost of water heating. Water is heated using energy from the sun and stored in flat-plate collectors or tanks. This option is especially attractive when combining financing options with federal tax deductions.

Gas or Electric?

There is a lot of confusion about whether gas or electric water heaters are more efficient. People tend to think that gas heaters are more efficient because they heat water quickly and are cheaper to run. Contrarily, it’s electric heaters that are more efficient. Imagine a gas stove top versus an electric stove top. The flame ignites on a gas stove top, heating the pan immediately. The electric stove top takes some time before it gets to full temperature. Yes, an open flame burns hotter. At the same time, gas is still less efficient for that same reason. An open flame means heat is transferring into the open air. A vent is necessary for gas-fired units, which waste generated energy. They also tend to need replacement sooner due to overworking.

Furthermore, the reason gas units are cheaper to run is that the cost of natural gas is lower than electricity. Once again, this has nothing to do with the efficiency of natural gas versus electricity. For a gas unit, you’ll probably pay more upfront and have lower operating costs overall. With an electric unit, those figures would be the opposite depending on exactly how efficient the electric system is. In other words, the costs between the two will balance out. However, if you choose an efficient electric water heater, you would see more savings overall.

Either way, you’ll need to check with your local code before deciding. In California, some municipalities do not allow natural gas in new construction. Also, an electric system does not guarantee a clean supply of electricity. California allows you to choose your electric supplier through Energy Choice programs. Unless you choose solar and wind providers over coal or nuclear, an electric unit may not have that much environmental benefit.

Factors of Efficiency / Efficiency Ratings

Energy Factor

The overall efficiency of a hot water heating system is determined by its Energy Factor. The energy Factor represents the amount of hot water produced per unit of fuel in a day. On average, ENERY STAR water heaters are highly efficient. For example, an ENERGY STAR-rated unit would have an energy factor of .65-.95. Efficient hot water heaters have a higher rating. For example, the highest energy factor currently available for a standard-style system is 4. The highest energy factor available for a solar system is 11. Keep in mind, that gas (measured in therms) and electric (measured in kW) fuels have different costs. So, fuel type is also a factor in the operating cost.

Solar Fraction

Solar fraction is a term that applies exclusively to solar water heaters. SF is used to relay what percentage of the system’s water production comes from solar energy. It’s calculated by dividing solar energy delivered to the tank by the total energy delivered to the tank. Ratings range from zero to one. Thus, the greater the number represents a higher portion of energy deriving from solar. To find the solar fraction and efficiency rating of solar systems, visit the website of the Solar Rating and Certification Corporation.

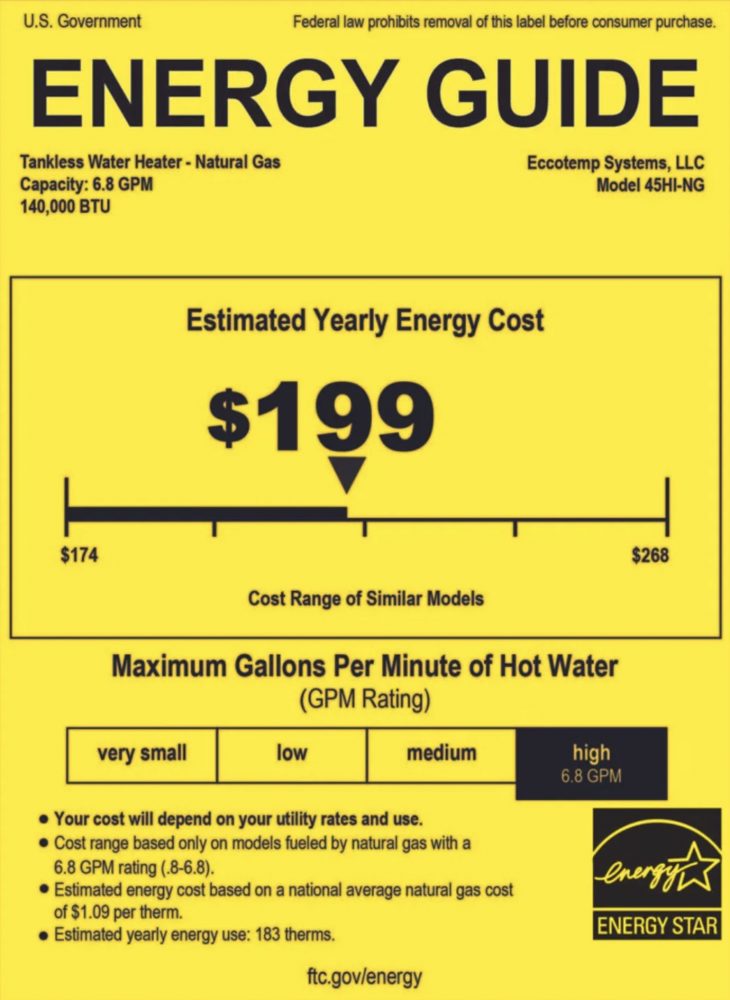

Input Ratings

You may have noticed the “140,000 BTU” rating on the yellow Energy Guide above. First of all, the BTU rating on a water heater stands for British Thermal Unit per Hour. A BTU is a measurement of heat. To be exact, 1 BTU represents the energy a system uses to heat one pound of water by 1 degree Fahrenheit. Therefore BTUs/hr depict how many pounds of water can be heated by 1 degree in an hour. Let’s use the example of a 30 Gallon capacity tank, which equates to about 250 pounds. So, a 25,000 BTU system could heat the entire tank in one hour. Efficient water heaters have a higher BTU rating.

Thermal Efficiency

Heating efficiency is a percentage rating on the portion of thermal energy that’s directly used to heat water. Well, you might be thinking, isn’t all of the energy used to heat water? Not exactly. Some amount of thermal energy is lost in the process of turning fuel into heat. Heat can be lost through ventilation, combustion, flues, or dispersed into the air while sitting in the tank, for instance. Typically, a water heater should be at least 80% efficient in order to get installation approval in California. That means 80% of the system’s energy is directly used to heat water. Anything above 90% is considered high efficiency and can gain additional compliance points.

Insulation

Insulation is required in some portions of the incoming and outgoing water pipelines to reduce thermal energy loss. Exactly how many feet and what thickness is determined by what code cycle applies to your permit and what kind of structure you’re dealing with. There are also other piping requirements such as for buried or recirculation pipes. An installer or contractor should always consult with a HERS Rater to make sure they are in compliance with all Title 24 regulations.

Sometimes, an architect or Title 24 Consultant may choose to include tank insulation in a set of plans in order to gain extra compliance points. The purpose of tank insulation is to increase thermal efficiency by decreasing thermal energy lost while hot water sits in the tank. Most efficient water heaters already have some built-in insulation lining the inside of the tank. Hence, you can not feel the heat coming off the outside of the tank. The other type of insulation is wrapped around the outside of the tank.

Standby Loss

Previously, we talked about how insulation is used in conjunction with water heating systems. This brings me to the next term, standby loss. Standby loss indicates what amount of energy is lost by water storage, expressed by BTU/hour or as a percentage of total energy. Naturally, gas water heaters have more standby loss because those systems require ventilation and they have a constant pilot light. Opposingly, tankless systems do not have any standby loss.

First-hour Rating / Flow Rate

First-hour rating, also known as flow rate, is the amount of hot water the system can produce in one hour. It’s portrayed as a percentage, which can be confusing at first. In order for you to understand this, I will explain how a standard water heater operates. As you use the hot water stored in the tank, new water is supplied to replenish itself. The water coming into the system has not yet been heated, and thus slowly drops the temperature throughout the storage tank. Therefore, if the first-hour rating is 70%, you can use 70% of the tank’s full capacity before running out of hot water. If the tank has a 30-gallon capacity, you get 21 gallons of usable water.

Alternatively, a tankless water heater uses Gallons Per Minute (GPM) instead of a first-hour rating. In other words, these systems do have limitations as to how much hot water can “flow” at one time. You should consult the Energy Guide in order to calculate how much hot water the system can process at once. For example, doing the laundry while taking a shower may still not be the best idea.